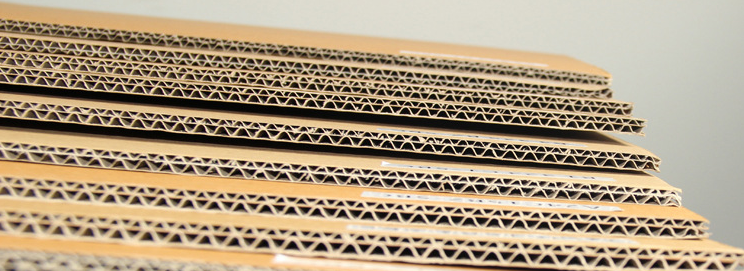

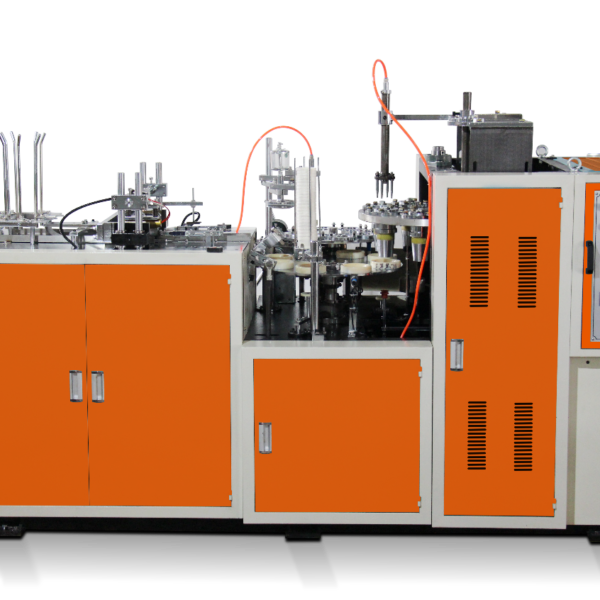

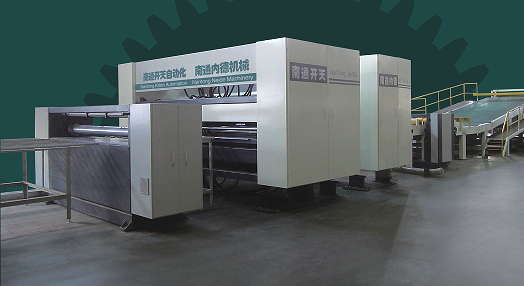

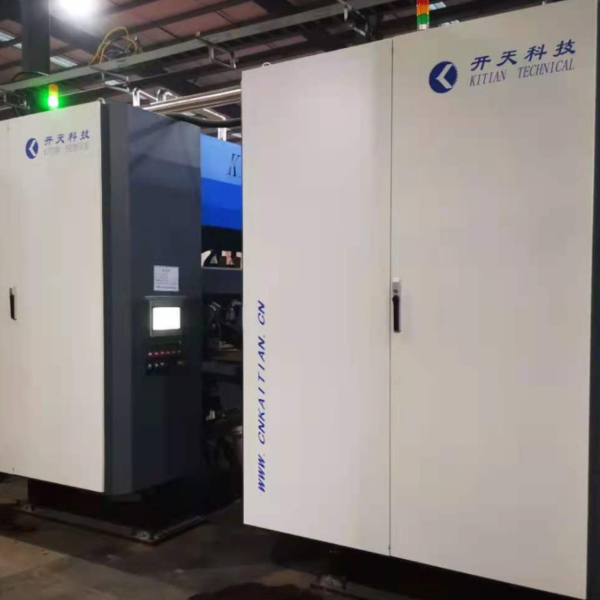

Automatic Seven Layer Corrugated Cardboard Production Line

1,00 EGP

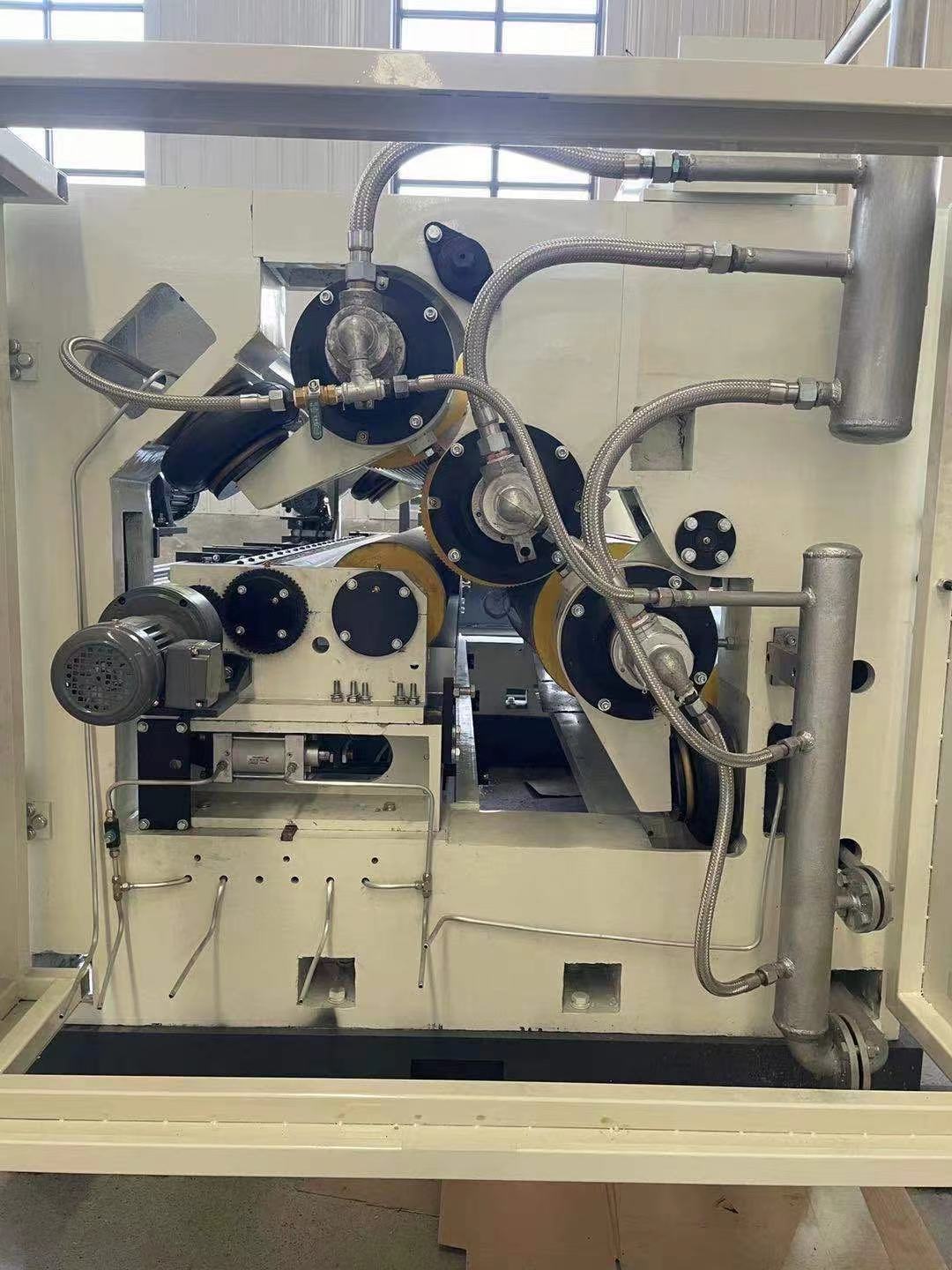

This production line based on the 16 years of experience in the production of carton machinery and developed the new product. Characterized by a high degree of automation, convenient operation and maintenance, production

-Technical Parameters:

| 1 | Effective width | 1800mm | 2 | Design produce speed | 150m/min |

|---|---|---|---|---|---|

| 3 | Three layer work speed | 100-140m/min | 4 | Five layer work speed | 90-120m/min |

| 5 | Seven layer work speed | ——————- | 6 | The highest change single speed | 100m/min |

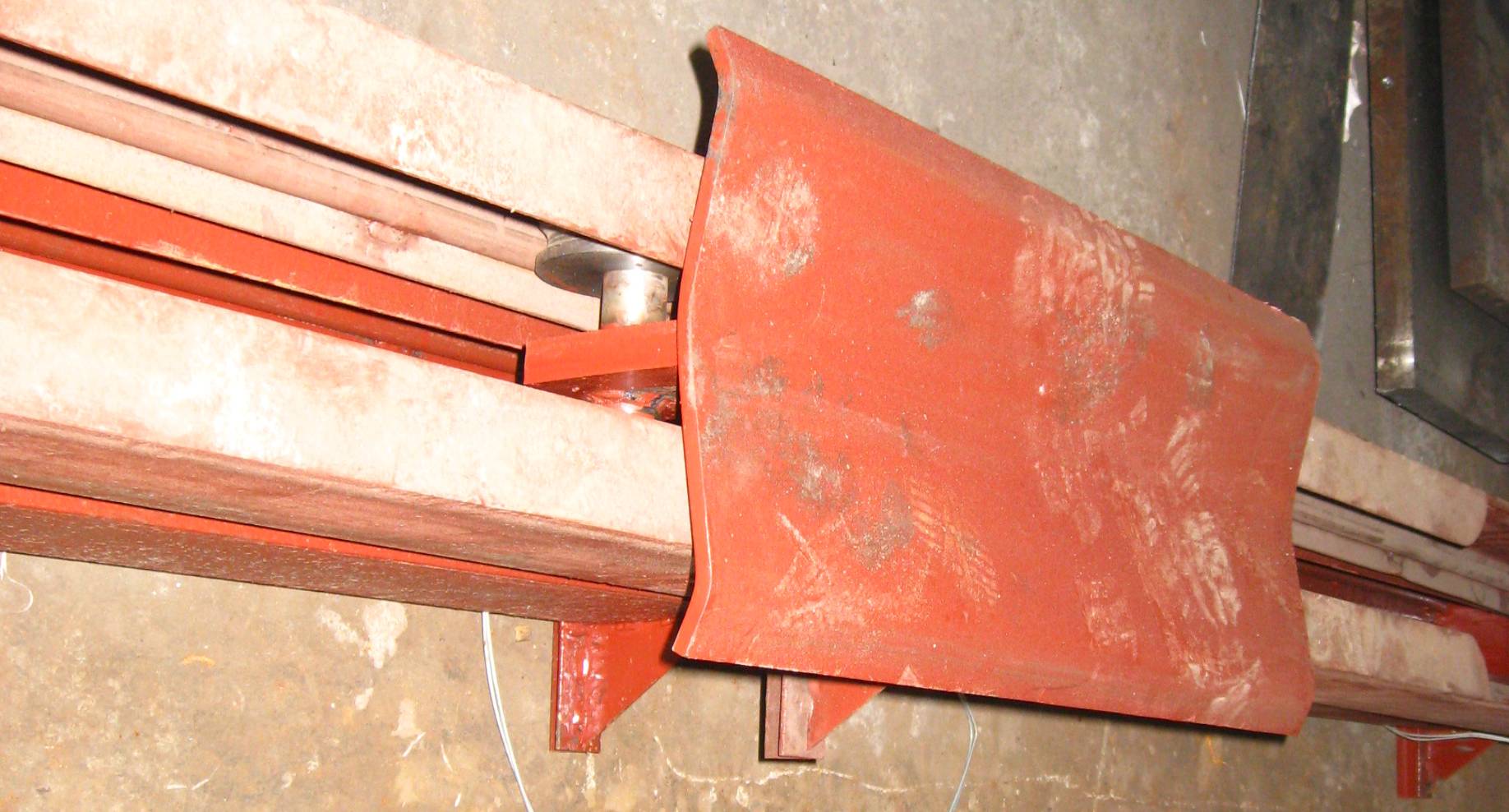

| 7 | Longitudinal separation accuracy | ±1mm | 8 | Cross-cutting precision | ±1mm |

| note | Speed the above targets required to achieve:effective width1800mm,Comply with the following standards and ensure the paper’s equipment condition 175 ℃ heating surface temperature. | ||||

| Top paper index | 100g/㎡–180g/㎡ Ring crush index(N.m/g)≥8 (Water containing8-10%) | ||||

| Core paper index | 80g/㎡–160g/㎡ Ring crush index(N.m/g)≥5.5 (Water containing8-10%) | ||||

| In paper index | 90g/㎡–160g/㎡ Ring crush index(N.m/g)≥6 (Water containing8-10%) | ||||

| 9 | Flute combination | ||||

| 10 | Steam requirement | The maximum pressure 16kg/cm2 | Common pressure10-12kg/cm2 | use4000kg/Hr | |

| 11 | Electricity demand | AC380V 50Hz 3PH | Total power≈220KW | Running Power≈150KW | |

| 12 | Compressed air | The maximum pressure 9kg/cm2 | Common pressure4-8kg/cm2 | use1m3/min | |

| 13 | space | ≈Lmin59m*Wmin10m*Hmin5m(The actual drawing to provider to provide audited prevail) | |||

المراجعات

لا توجد مراجعات بعد.

المراجعات

لا توجد مراجعات بعد.